A well pump control box is an electrical device that is used to control the operation of a well pump. It typically includes a pressure switch, which turns the pump on when the water pressure drops below a certain level, and a timer, which turns the pump off after a set amount of time. Some well pump control boxes also include a low-water cut-off switch, which turns the pump off if the water level in the well drops too low.

Well pump control boxes are an important part of any well system, as they help to protect the pump from damage and ensure that the water supply is always available. Without a well pump control box, the pump could run continuously, which would shorten its lifespan and could also lead to flooding.

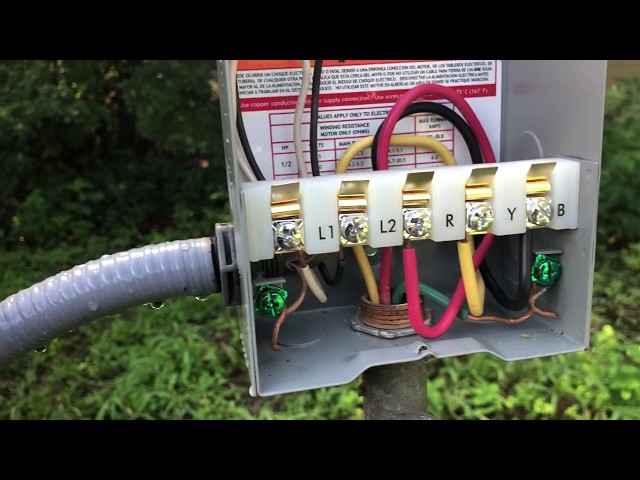

Well pump control boxes are typically installed by a qualified electrician. They are available in a variety of sizes and styles, so it is important to choose one that is appropriate for the specific well and pump system.

well pump control box

A well pump control box is an essential component of any well system, as it helps to protect the pump from damage and ensures that the water supply is always available. Here are six key aspects of well pump control boxes:

- Protection: Well pump control boxes protect the pump from damage by turning it off if the water pressure drops too low or if the water level in the well drops too low.

- Control: Well pump control boxes allow you to control the operation of the pump, such as setting the pressure at which the pump turns on and off.

- Monitoring: Well pump control boxes can be equipped with sensors that monitor the pressure and water level in the well, providing you with valuable information about the status of your well system.

- Convenience: Well pump control boxes are convenient to use, as they can be set to automatically turn the pump on and off as needed.

- Safety: Well pump control boxes can help to prevent accidents, such as flooding, by turning the pump off if the water pressure drops too low.

- Efficiency: Well pump control boxes can help to improve the efficiency of your well system by ensuring that the pump is only running when needed.

These are just a few of the key aspects of well pump control boxes. By understanding these aspects, you can make sure that your well system is operating safely and efficiently.

Protection

Well pump control boxes play a crucial role in protecting well pumps from damage. They do this by monitoring the water pressure and water level in the well, and turning the pump off if either of these falls below a safe level.

- Pressure Protection: Well pump control boxes protect the pump from damage caused by low water pressure. When the water pressure drops below a certain level, the control box will turn the pump off. This prevents the pump from running dry, which can cause the pump to overheat and fail.

- Water Level Protection: Well pump control boxes also protect the pump from damage caused by low water levels. When the water level in the well drops below a certain level, the control box will turn the pump off. This prevents the pump from running without water, which can cause the pump to overheat and fail.

By protecting the pump from damage, well pump control boxes help to ensure a reliable water supply for your home or business.

Control

Well pump control boxes provide users with the ability to control the operation of their well pumps, offering a range of benefits and applications. Here are a few key aspects to consider:

- Pressure Settings: Well pump control boxes allow users to set the pressure at which the pump turns on and off. This is important for ensuring that the pump is operating efficiently and delivering the desired water pressure to the home or business. Proper pressure settings can also help prevent water hammer and other issues.

- Manual Control: In addition to automatic operation, well pump control boxes often provide manual control options. This allows users to turn the pump on or off as needed, regardless of the pressure settings. This can be useful for tasks such as priming the pump or performing maintenance.

- Run Time Monitoring: Some well pump control boxes include run time monitoring features. This allows users to track how long the pump has been running, which can be helpful for troubleshooting issues or planning maintenance.

- Alarm Functions: Advanced well pump control boxes may include alarm functions that alert users to potential problems, such as low water pressure or pumps. This can help prevent damage to the pump and ensure a reliable water supply.

Overall, the control features provided by well pump control boxes empower users to manage the operation of their well pumps effectively, ensuring optimal performance and a reliable water supply.

Monitoring

Monitoring the pressure and water level in a well is essential for ensuring the proper operation of a well pump and the overall integrity of the well system. Well pump control boxes play a crucial role in this monitoring process, offering several key benefits:

- Real-Time Data: Well pump control boxes provide real-time data on the pressure and water level in the well, allowing for continuous monitoring of the well’s performance. This information is vital for identifying potential issues and taking corrective actions promptly.

- Pressure Monitoring: By monitoring the water pressure, well pump control boxes can detect any abnormalities that may indicate leaks, blockages, or other problems in the well system. This helps prevent damage to the pump and ensures a consistent water supply.

- Water Level Monitoring: Monitoring the water level in the well is essential for preventing the pump from running dry, which can lead to overheating and damage. Well pump control boxes with water level sensors can alert users to low water levels, allowing them to take appropriate action.

- Predictive Maintenance: The data collected by well pump control boxes can be used for predictive maintenance, enabling users to identify potential problems before they become critical. By analyzing trends and patterns in the pressure and water level readings, users can schedule maintenance or repairs proactively, minimizing downtime and extending the lifespan of the well system.

Overall, the monitoring capabilities of well pump control boxes are essential for maintaining a well-functioning and reliable well system. By providing real-time data, detecting abnormalities, and facilitating predictive maintenance, these control boxes help ensure a safe and efficient water supply.

Convenience

Convenience is a key aspect of well pump control boxes, offering significant benefits to users in terms of ease of operation and maintenance.

- Automated Operation: Well pump control boxes eliminate the need for manual intervention to turn the pump on and off. Once configured, the control box takes care of these tasks automatically, based on pre-defined pressure or water level settings. This automation provides peace of mind and saves time and effort for users.

- Remote Monitoring: Advanced well pump control boxes offer remote monitoring capabilities, allowing users to access real-time data and control the pump remotely. This can be particularly useful for systems in remote locations or for users who want to monitor their well system from anywhere.

- Simplified Maintenance: Well pump control boxes simplify maintenance by providing diagnostic features and alerts. They can monitor pump performance, detect potential issues, and notify users when maintenance is required. This proactive approach helps prevent unexpected breakdowns and extends the lifespan of the well system.

In summary, the convenience offered by well pump control boxes is a major advantage, making them an essential component of modern well systems. Automated operation, remote monitoring, and simplified maintenance contribute to a user-friendly experience and ensure the smooth and efficient operation of the well system.

Safety

Well pump control boxes play a critical role in preventing accidents, particularly those related to flooding. Their ability to monitor water pressure and turn off the pump in the event of a drop below a safe level is a crucial safety feature.

Flooding can occur due to various reasons, such as a burst pipe, a malfunctioning pump, or a power outage. In the absence of a well pump control box, a malfunctioning pump or a power outage can lead to continuous pumping of water into the home, resulting in flooding. The water pressure drop caused by these events is detected by the control box, which promptly turns off the pump, preventing further water accumulation and potential damage to the property.

The importance of this safety feature cannot be overstated. Flooding can cause significant damage to a home’s structure, furnishings, and personal belongings. The ability of well pump control boxes to prevent such accidents provides peace of mind and protects homeowners from costly repairs and potential hazards.

In conclusion, the safety aspect of well pump control boxes is paramount. Their ability to monitor water pressure and turn off the pump in response to a drop in pressure is a vital safeguard against flooding and its associated risks. Homeowners who rely on well water systems should ensure that their pumps are equipped with properly functioning control boxes to protect their homes and ensure their safety.

Efficiency

Well pump control boxes play a pivotal role in enhancing the efficiency of well systems by optimizing pump operation and minimizing energy consumption. Their ability to monitor water pressure and control pump activity based on predefined settings leads to several key efficiency-related benefits:

- Demand-Based Operation: Well pump control boxes ensure that the pump operates only when there is a demand for water. By monitoring water pressure, they can detect when water is being used and activate the pump accordingly. This eliminates unnecessary pump run time and reduces energy waste.

- Pressure Regulation: Well pump control boxes maintain optimal water pressure by adjusting pump operation based on pressure readings. This prevents the pump from running excessively to maintain high pressure levels, which can strain the pump and increase energy consumption.

- Leak Detection: Some advanced well pump control boxes have leak detection capabilities. They can identify gradual pressure drops that may indicate leaks in the system, enabling timely repairs and preventing water loss and wasted energy.

- Run Time Optimization: Well pump control boxes can track pump run time and adjust operation schedules accordingly. This ensures that the pump runs for optimal durations, avoiding unnecessary wear and tear and maximizing energy efficiency.

By implementing these efficiency-enhancing measures, well pump control boxes help reduce energy consumption, extend pump life, and minimize water waste. They are an essential component of any well system, contributing to both economic and environmental sustainability.

FAQs about Well Pump Control Boxes

Well pump control boxes play a crucial role in the operation and safety of well systems. Here are answers to some frequently asked questions about these devices:

Question 1: What is the purpose of a well pump control box?

A well pump control box is designed to automatically start and stop a well pump based on water pressure or water level. It protects the pump from damage due to dry running or excessive pressure, and ensures a consistent water supply.

Question 2: How does a well pump control box work?

Well pump control boxes typically use a pressure switch or water level sensor to monitor the well’s conditions. When the water pressure drops below a preset level, the pressure switch activates the pump. When the pressure or water level reaches the desired set point, the control box turns the pump off.

Question 3: What are the benefits of using a well pump control box?

Well pump control boxes offer several benefits, including protection against pump damage, automatic operation, improved water pressure regulation, and prevention of water waste due to leaks or excessive pumping.

Question 4: How do I choose the right well pump control box for my system?

Consider the type of well pump you have, the desired pressure range, and any additional features you may need, such as low-water cut-off protection or remote monitoring capabilities.

Question 5: How often should I service my well pump control box?

It is recommended to have your well pump control box inspected and serviced by a qualified professional at least once a year. Regular maintenance can help ensure optimal performance and extend its lifespan.

Question 6: What are some common problems associated with well pump control boxes?

Common issues include faulty pressure switches, clogged sensors, and electrical problems. If you experience any issues with your well pump control box, it is important to contact a qualified electrician or pump specialist for assistance.

Summary: Well pump control boxes are essential components of well systems, providing protection, automation, and efficiency. By understanding their purpose, operation, and maintenance requirements, you can ensure the reliable and safe operation of your well system.

Transition to the next article section: For more information on well pump control boxes and their importance in well systems, refer to the following resources: [Insert links to relevant articles or resources]

Well Pump Control Box Tips

Well pump control boxes are essential components of well systems, ensuring the efficient and safe operation of the pump. Here are five tips to optimize the performance and longevity of your well pump control box:

Tip 1: Regular Maintenance

Schedule regular inspections and maintenance for your well pump control box. A qualified electrician or pump specialist can inspect the electrical connections, check the pressure switch or water level sensor, and ensure the overall integrity of the device.

Tip 2: Proper Sizing

Ensure that the well pump control box is appropriately sized for your well system. An undersized control box may not be able to handle the electrical load of the pump, while an oversized control box may not provide optimal protection.

Tip 3: Pressure Switch Adjustment

Adjust the pressure switch settings to match the specific requirements of your well system. The cut-in pressure should be set slightly below the minimum operating pressure of the pump, while the cut-out pressure should be set slightly above the maximum operating pressure.

Tip 4: Water Level Monitoring

If your well pump control box has a water level sensor, ensure that it is positioned correctly to accurately monitor the water level in the well. A faulty or improperly positioned sensor can lead to inaccurate readings and potential pump damage.

Tip 5: Electrical Safety

Always follow proper electrical safety precautions when working on your well pump control box. Ensure that the power is turned off before performing any maintenance or repairs. Use insulated tools and wear appropriate safety gear.

Summary: By following these tips, you can maintain the optimal performance and longevity of your well pump control box. Regular maintenance, proper sizing, accurate pressure switch adjustment, water level monitoring, and adherence to electrical safety guidelines will ensure the reliable and safe operation of your well system.

Conclusion

Well pump control boxes play a pivotal role in the operation, safety, and efficiency of well systems. They protect pumps from damage, ensure consistent water pressure, and prevent water waste. Understanding the functions, benefits, and maintenance requirements of well pump control boxes is essential for homeowners and professionals alike.

By choosing the right control box for your well system, maintaining it regularly, and following proper electrical safety guidelines, you can ensure the reliable and long-lasting performance of your well. A well-functioning well pump control box is a crucial component of a safe and efficient water supply system.

Youtube Video: